Block Making Machine

Discover our latest technology hollow block machines, the perfect combination of innovation and durability.

Our hollow block machines, distinguished by their easy installation and extremely practical use, allow you to easily produce the hollow block models you desire.

25+ Countries

successfully installed

700+ Customers

Happy Customers

Different Capacity

Our machines available with different capacity

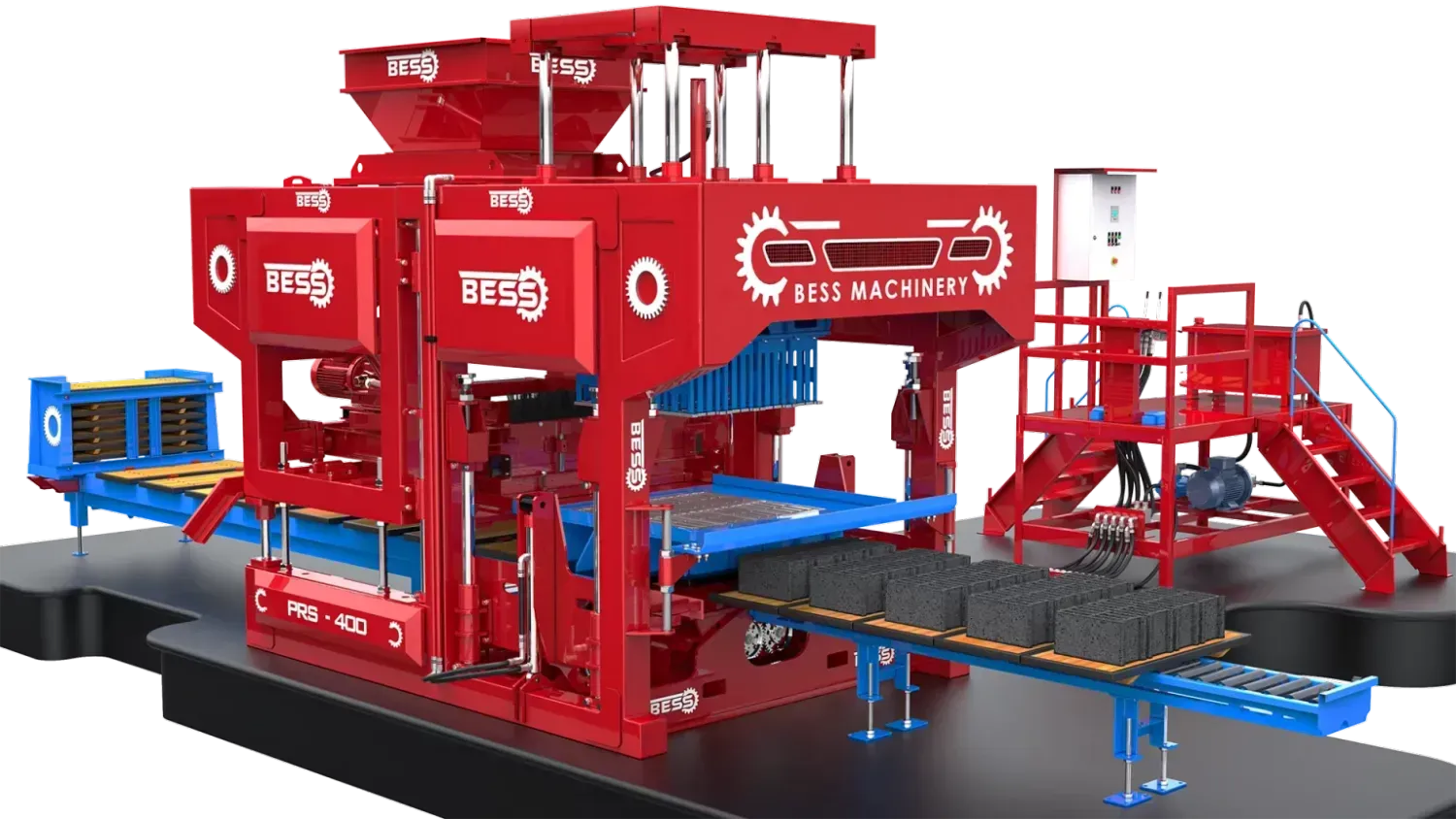

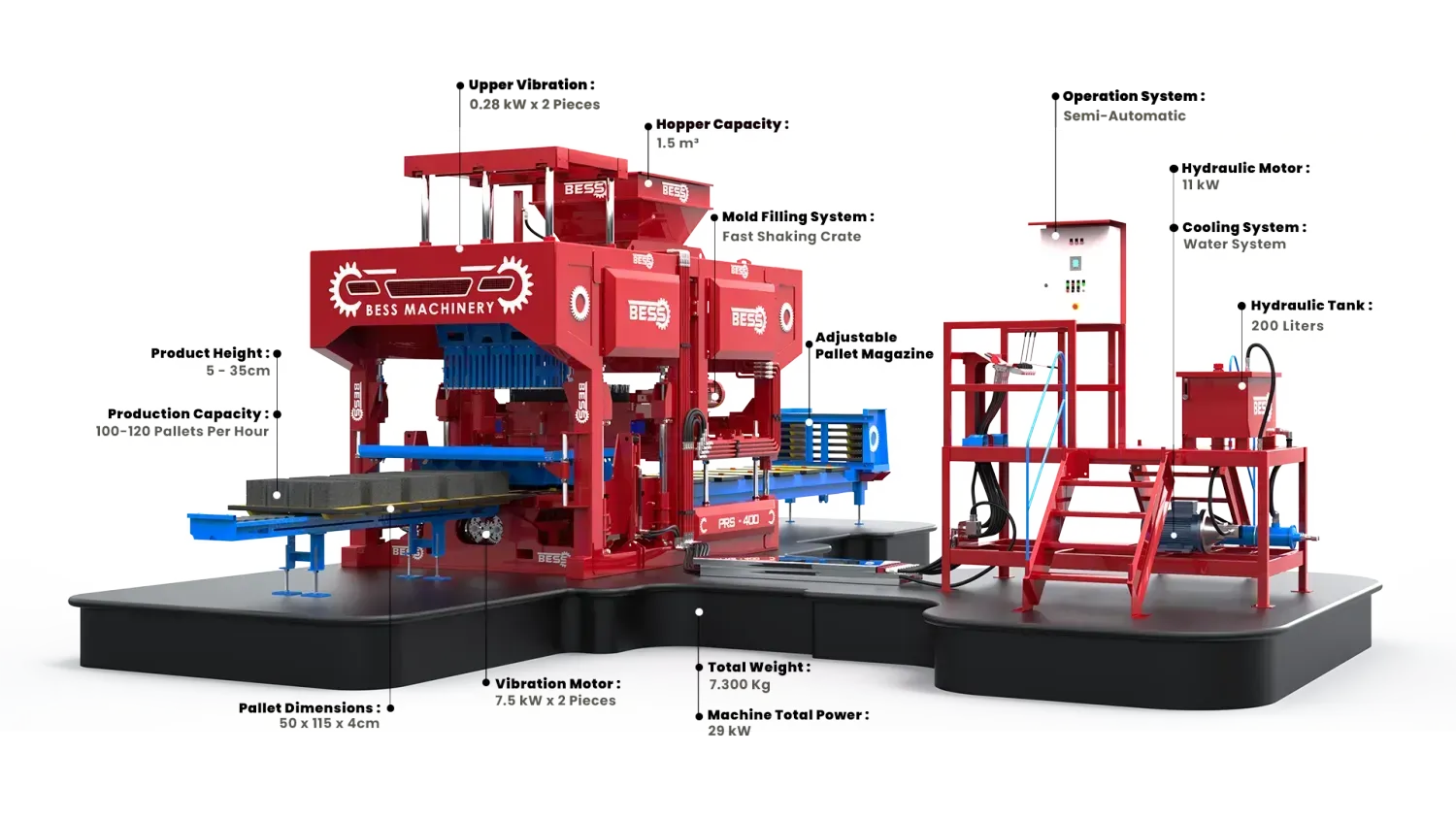

PRS 400 Semi-Automatic Hollow Block Machine

The PRS 400 semi-automatic hollow block machine is built with the power of technology to prioritize performance and reliability. It is designed to offer customized solutions to meet your needs and optimize your workflow. discover the full potential of this advanced technology machine by reviewing detailed technical specifications…

Installation and Operational Details

Semi-automatic, operator-controlled system

Manual pallet transport

Total personnel needed: 7 people

Suitable for 24-hour operation

Recommended area: 2,000 m²

Concrete foundation required for the machine: 300 m²

Roof covering not necessary

Total energy requirement: 50 kW

Recommended generator power for the plant: 175 kVA

Number of containers required for transportation: 1 x 40′ HC container

Special Design Reinforced by Modern Technology

Designed in international shipping dimensions: 225x335x320 cm

Capable of producing concrete products from 5 cm up to 35 cm in height.

Reinforced chassis supports: 150x150x5 mm

Large-capacity mortar hopper with support: 1.5 m³

Additional vibration damping wedges

Special rubber wedges to reduce impact

Replaceable steel design for wearing surfaces

Technical Specifications

With the PRS 400 semi-automatic hollow block machine, you can produce over 600 concrete block models including all kinds of hollow blocks, solid blocks, paving blocks, hollow floor blocks (Asmolen), curbstones, rain gutters, etc., ranging from 5 cm to 35 cm in height. Meet the needs of different sectors and highlight your products with creative designs. Explore the detailed production capacity of the PRS 400 machine.

4.9 out of 5.0 stars

Our company, with a focus on customer satisfaction, has operated in 52 countries worldwide and completed over 600 projects, continuously expanding our customer portfolio. We are ready to provide customized solutions and contribute to your success stories.

Explore our references to closely see the value and benefits of working with us.

Frequently Asked Questions.

The recommended installation and production area for the PRS 400 semi-automatic hollow block machine is 2,000 m²

A total of 7 personnel are required for the efficient operation of a semi-automatic plant: 1 machine operator, 1 mixer operator, 3 pallet transport staff, 1 pallet loading staff, and 1 raw material loading staff.

Yes, vibrating machines, especially hollow block machines, can experience fractures and cracks in their frames due to the vibration and pressing systems they operate with. These machines undergo high levels of stress on their chassis. However, we minimize the impact of vibration on the frame by using special reinforcements and damping wedges in our machines. This ensures robust and long-lasting solutions for our users.

The pallet dimensions for the PRS 400 are 50×115 cm, and they can be made from plastic, wood, or metal. In semi-automatic systems, the products are transported to the curing area using pallet carrying trolleys

The most important factors affecting the performance of the machine’s hydraulic system are the quality and viscosity of the hydraulic oil, operating temperature, oil cleanliness and proper filtration, correct pressure and flow settings, high-quality components, proper installation, and regular maintenance. Each of these factors ensures the system operates efficiently and reliably